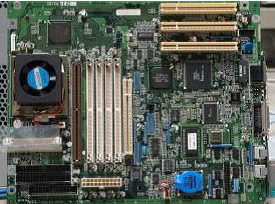

Motherboard

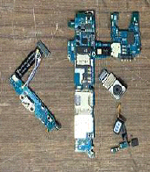

CPU chips

CPU chips

CPU chips

CPU chips

E.g. hard disk crushing, degaussing, punching of hard drives etc.

Degaussing

Punching

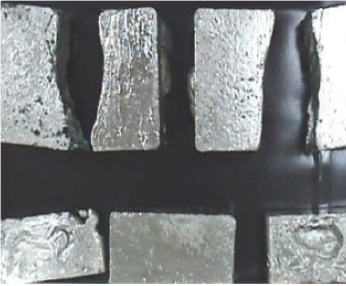

Gold:

Silver:

Platinum:

Palladium:

:

: